Minimal Operator Intervention, Maximum Uptime

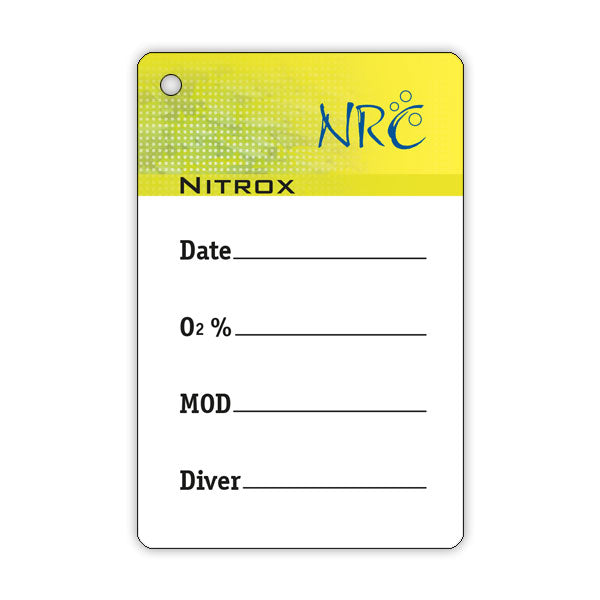

NRC International is a global leader in nitrox systems and a pioneer in modern nitrox diving. Since 2000, it has shaped the industry with initiatives like the widely adopted 'Nitrox for Free' program and training standards still used today. For over two decades, leading dive centers around the world have relied on NRC’s professional-grade technology. It is engineered for exceptional reliability, regardless of the production method.